HOW TO: Splice lead core

Lead core is simply a thin lead wire covered by a braided sheath and has been used by anglers for many years. It is remarkably adaptable, well suited to making hook lengths as well as strong and abrasion-resistant leaders which sit naturally on the lake bed, out of the way of feeding fish.

Lead core has a reputation for being difficult to splice but I aim to show you in a few steps that this doesn't have to be the case.

What you need

Tools 1. Super glue

1. Super glue

2. Scissors

3. Splicing needles

4. Rig pullers

Tackle 1. Lead core

1. Lead core

Method

Step 1 Cut your required length of leadcore using the scissors. Then fold back the end 20cm parallel with the main leadcore.

Cut your required length of leadcore using the scissors. Then fold back the end 20cm parallel with the main leadcore.

Step 2 Push the outer braided skin back to expose 8 cm of the inner lead wire, and break this off.

Push the outer braided skin back to expose 8 cm of the inner lead wire, and break this off.

Step 3 With the 8cm of lead wire broken off allow the braid to slip back over the lead wire so you end up with 8cm of braid with no wire inside it.

With the 8cm of lead wire broken off allow the braid to slip back over the lead wire so you end up with 8cm of braid with no wire inside it.

Now inset the splicing needle at the point where the braid skin meets the start of the lead wire to a depth of 3.5cm.

Step 4 Now pass the splicing needle out through the braid.

Now pass the splicing needle out through the braid.

Step 5 Place the end of the braid skin into the gate of the splicing needle and gentle ease the needle back pulling the skin into the braid.

Place the end of the braid skin into the gate of the splicing needle and gentle ease the needle back pulling the skin into the braid.

Step 6 Gentle pull the splicing needle back through the braid until it is all the way through.

Gentle pull the splicing needle back through the braid until it is all the way through.

Step 7 Now tease the loop in the braid until you get the correct size you need. When you have the correct size tension the loop with a rig puller until the braided loop is tight.

Now tease the loop in the braid until you get the correct size you need. When you have the correct size tension the loop with a rig puller until the braided loop is tight.

Step 8 Once you are happy with the loop super glue the braid to lock it in place.

Once you are happy with the loop super glue the braid to lock it in place.

Repeat steps 1 to 8 to have a lead core leader with a loop at both ends, or alternatively follow the next steps to place a swivel at the other end of the leader.

Step 9 With the other end of the leader follow steps 1 to 4. Now add a swivel onto the splicing needle before you pull the braid back into it self.

With the other end of the leader follow steps 1 to 4. Now add a swivel onto the splicing needle before you pull the braid back into it self.

Step 10 Gently pull the splicing needle back through the braid until it is all the way through.

Gently pull the splicing needle back through the braid until it is all the way through.

Step 11 Once you are happy with the loop super glue the braid to lock it in place.

Once you are happy with the loop super glue the braid to lock it in place.

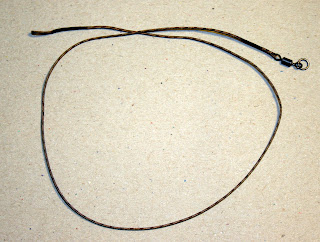

Now you have the perfect leadcore leader. With this skill you can now easily make a leader to suit your exact requirements at a fraction of the cost of shop made leaders.

Tight lines!

Labels: tips

0 Comments:

Post a Comment

<< Home